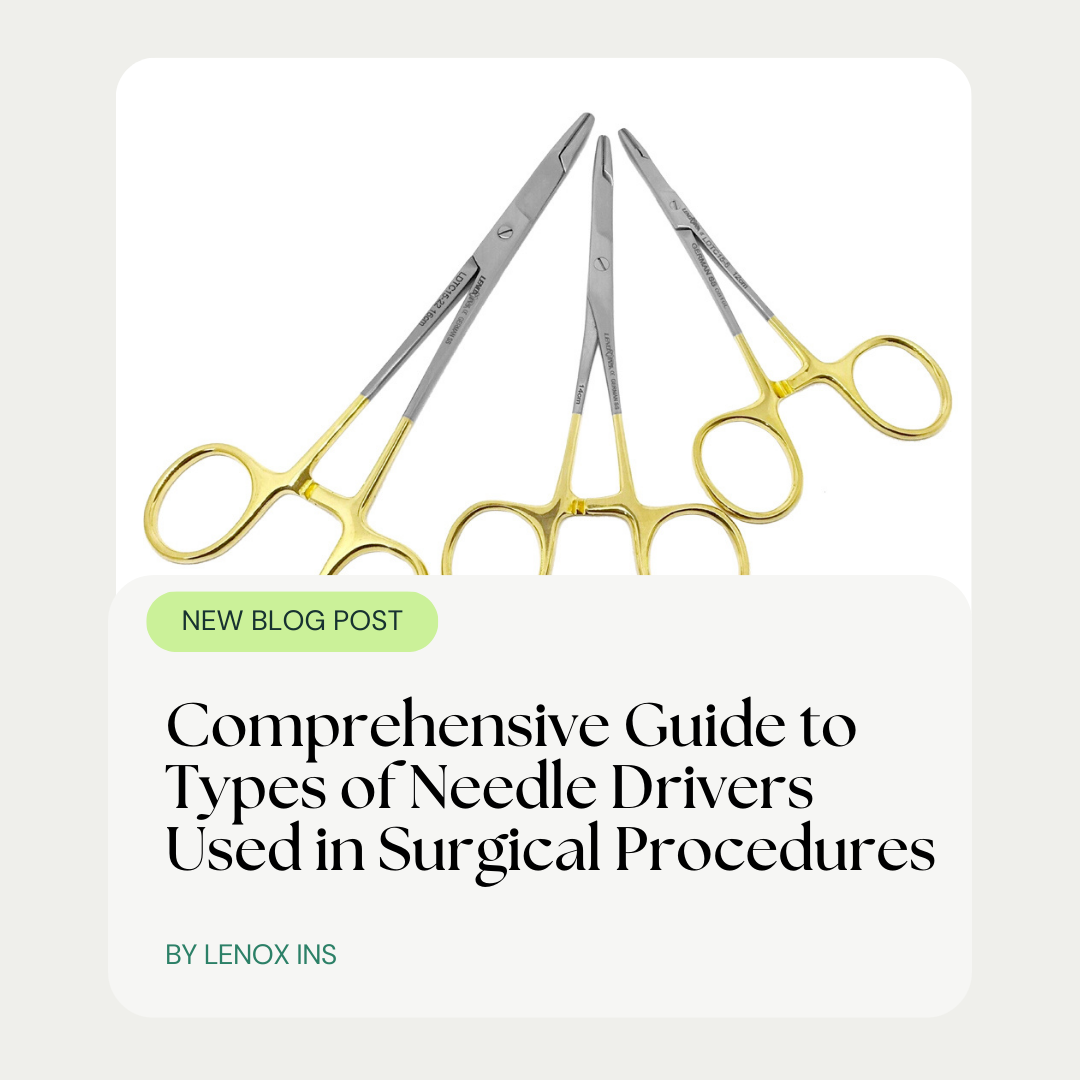

Comprehensive Guide to Types of Needle Drivers Used in Surgical Procedures

- lenoxinstro

- October 30, 2024

- Dental Instruments, Dental Surgical, Needle Holder

Selecting the right needle driver is crucial for successful surgical outcomes. A common challenge many surgeons face is finding the appropriate tool that ensures precision while handling delicate sutures and cannulas. This guide provides a comprehensive overview of the types of needle drivers, including the popular Webster needle holder, their design classifications, and their specific applications in various procedures. By reading this content, healthcare professionals will gain valuable insights to aid in selecting the best needle driver for patient care, ultimately enhancing their efficacy in surgery. Webster needle holder

Key Takeaways

- Needle drivers are essential tools for various surgical disciplines, enhancing precision in suturing

- The material choice influences durability and effectiveness in surgical procedures

- Ergonomic design in needle drivers reduces hand fatigue during lengthy operations

- Proper maintenance and cleaning are vital for the longevity of needle drivers

- Selecting the suitable needle driver is crucial for achieving optimal patient outcomes

Understanding the Role of Needle Drivers in Surgery

Needle drivers play a critical role in suturing techniques across various surgical procedures, including eye surgery and reconstructive surgery. Their precision is enhanced by components like tungsten carbide jaws and stainless steel construction, contributing to efficiency during operations. Understanding the anatomy and function of needle drivers, including features like the ratchet mechanism, helps overcome surgical challenges effectively.

Importance of Needle Drivers in Suturing Techniques

Needle drivers are essential instruments in various surgical disciplines, including neurosurgery, laparoscopy, general surgery, and urology. These tools enhance precision in suturing techniques, allowing surgeons to manipulate tissue with accuracy. Additionally, their design enables surgeons to achieve secure knots, minimizing tissue trauma and promoting optimal healing for patients. Needle drivers come from authoritative publishers. We’ll secure the quantity you need and in the right time frame.

| Surgical Discipline | Role of Needle Drivers |

|---|---|

| Neurosurgery | Facilitates intricate suturing around delicate neural tissues. |

| Laparoscopy | Offers enhanced dexterity in limited spaces, ensuring effective closure of small incisions. |

| General Surgery | Supports a wide range of suturing needs across various procedures, enhancing overall efficiency. |

| Urology | Optimizes suturing for tissue repairs, contributing to better patient outcomes. |

Components and Anatomy of a Needle Driver

A needle driver typically consists of several key components that enhance its functionality in surgical settings, particularly in orthopedic surgery. These instruments may include plastic grips for better handling and control, as well as precision jaws that assist in grasping needles securely to create knots. Understanding the various types of needle drivers, including those designed for specialized roles such as retractors, allows surgeons to select the most appropriate tools for each procedure, leading to improved patient outcomes and reduced procedural complications.

Enhancing Precision and Efficiency With Needle Drivers

Needle drivers significantly enhance precision and efficiency during surgery by providing a reliable grip on needles and facilitating the suturing process. When using steel needle drivers, surgeons can apply the necessary pressure while minimizing the risk of tissue damage, especially in delicate procedures such as plastic surgery. Their ergonomic design, which may include forceps features, allows for smooth manipulation and secure knot formation, ultimately contributing to better patient care and outcomes.

| Key Advantages of Needle Drivers | Description |

|---|---|

| Precision | Enables accurate needle placement and consistent knot tying. |

| Material Quality | Stainless steel construction ensures durability and resistance to wear. |

| Ergonomic Design | Facilitates extended use, reducing hand fatigue during complex procedures. |

| Versatility | Applicable across various surgical specialties, including plastic surgery and orthopedics. |

Overcoming Surgical Challenges Using Proper Needle Drivers

Proper use of needle drivers can significantly address challenges faced during surgical procedures, particularly in disciplines like otorhinolaryngology. The design of needle drivers, particularly their jaws, ensures a secure grip on sutures, minimizing the risk of slippage and enhancing precision when navigating delicate anatomical structures. Additionally, when combined with specialized surgical scissors, these instruments facilitate more efficient handling and knot tying, ultimately reducing the potential for complications such as scarring or improper healing.

Needle drivers are not all the same. Understanding how they differ in design reveals their unique strengths in the operating room.

Classification of Needle Drivers Based on Design

Classification of Needle Drivers Based on Design

This section explores the classification of needle drivers based on design, highlighting key differences between straight and curved needle drivers and their applications in surgical sutures. It compares locking and non-locking designs, examines various handle designs and their impacts on usability, and discusses material options, including stainless steel and tungsten carbide. Understanding these classifications is essential for choosing the right needle driver for procedures such as biopsies and surgeries involving trocars.

Differences Between Straight and Curved Needle Drivers

Straight and curved needle drivers serve distinct purposes in surgical procedures, particularly in contexts like microsurgery where precision is vital. Straight needle drivers offer superior visibility and access in straightforward wound closures, making them preferable for typical suturing tasks. In contrast, curved needle drivers allow physicians to navigate around critical structures and tight spaces, providing enhanced control and placement of sutures in challenging anatomical areas. Both types can be made from materials such as titanium, ensuring durability and facilitating effective sterilization processes required for maintaining surgical instruments.

Comparing Locking and Non-Locking Needle Drivers

Locking and non-locking needle drivers, both types of surgical instruments, serve vital roles in various procedures, including abdominal surgery. Locking needle holders provide a secure grip, minimizing the risk of accidental needle release, which can lead to injury during complex suturing tasks. In contrast, non-locking designs allow for more flexibility and quick adjustments, making them preferable in scenarios where rapid movement is essential; this distinction is particularly noted in studies found in medical resources such as Medline, aiding surgeons in selecting the most suitable needle holder for their needs.

Various Handle Designs and Their Impacts

The design of handles on needle drivers significantly influences a surgeon‘s ability to perform precise suturing. For instance, angled handles allow for improved access in tight surgical spaces, enhancing the surgeon‘s control over the instrument, while ergonomic finger grips minimize hand fatigue during lengthy procedures. Webster needle holders are an excellent example of this, as their compact design and well-placed finger grips enable secure needle handling in delicate situations, ensuring optimal outcomes for patients.

- Importance of handle design in needle drivers

- Impact of angles on access and control

- Ergonomic features reducing surgeon fatigue

- Examples of specialized needle holders like Webster needle holders

Material Options: Stainless Steel and Tungsten Carbide

Needle drivers can be constructed from stainless steel or tungsten carbide, each offering distinct advantages in surgical procedures. Stainless steel is widely used for its resistance to corrosion and ability to withstand repeated sterilization, helping to minimize infection risks during surgeries. In contrast, tungsten carbide needle drivers provide superior durability and sharper precision, making them particularly suitable for complex surgeries, including those that require a needle driver with scissors integrated into the design. Understanding these material distinctions aids surgeons in selecting the most effective tools for their specific needs.

- Material options for needle drivers include stainless steel and tungsten carbide.

- Stainless steel offers corrosion resistance and infection control.

- Tungsten carbide provides enhanced durability and precision.

- Designs include variations like a needle driver with scissors for added functionality.

Understanding the various designs of needle drivers opens the door to their practical applications. In the next section, common types reveal their unique functions and the tasks they excel at.

Common Types of Needle Drivers and Their Uses

This section provides an overview of common types of needle drivers used in surgical procedures, emphasizing their specific applications. Mayo-Hegar needle drivers are highlighted for general surgery, while Olsen-Hegar drivers incorporate scissor functions for versatile use. Castroviejo needle drivers are designed for microsurgical tasks, and Mathieu needle drivers feature a unique spring mechanism. Lastly, Gillies needle drivers are recognized for their effectiveness in delicate surgical tasks. Castroviejo needle drivers are designed for microsurgical tasks, and Mathieu needle drivers feature a unique spring mechanism. Lastly, Gillies needle drivers are recognized for their effectiveness in delicate surgical tasks.

Mayo-Hegar Needle Drivers in General Surgery

Mayo-Hegar needle drivers are widely used in general surgery due to their sturdy construction and reliable performance. These instruments feature a locking mechanism that secures the needle effectively, allowing surgeons to maintain control during the suturing process. Their ergonomic design helps reduce hand fatigue, making them suitable for prolonged use in a variety of surgical procedures, from closing incisions to repairing tissues, ultimately enhancing patient safety and outcomes.

Olsen-Hegar Needle Drivers With Scissor Functions

Olsen-Hegar needle drivers are a popular choice among surgeons due to their unique integrated scissor function, which enhances efficiency during procedures. These instruments streamline the suturing process by allowing surgeons to grasp, manipulate, and cut sutures without needing to switch tools, thereby reducing operation time and improving overall workflow. Their ergonomic design ensures comfortable handling, making them particularly suitable for complex surgeries where precision and speed are paramount.

Castroviejo Needle Drivers for Microsurgical Procedures

Castroviejo needle drivers are indispensable tools in microsurgical procedures, prized for their precision and ability to navigate intricate anatomical spaces. These instruments feature a unique design, which includes finely tapered jaws that ensure a secure grip on delicate sutures, allowing surgeons to execute complex repairs with confidence. Their application in high-stakes surgeries, such as ophthalmic and reconstructive surgeries, underscores their value in enhancing surgical outcomes and minimizing tissue trauma, ultimately facilitating better recovery for patients. Castroviejo needle holders

Mathieu Needle Drivers and Their Spring Mechanism

Mathieu needle drivers are characterized by their unique spring mechanism, which allows for improved handling and control during suturing tasks. This mechanism provides a reliable grip, ensuring that the needle remains secure throughout the suturing process, making them particularly useful in delicate surgeries such as otolaryngology and plastic surgery. By minimizing the need for constant manual gripping, surgeons can focus on precision and efficiency, leading to better patient outcomes.

- Mathieu needle drivers feature a spring mechanism for enhanced control.

- They provide a secure grip on needles, improving handling during suturing.

- Ideal for delicate procedures, such as those in otolaryngology and plastic surgery.

- Reduces manual fatigue, enabling surgeons to focus on precision.

Gillies Needle Drivers for Delicate Surgical Tasks

Gillies needle drivers are specifically designed for delicate surgical tasks, particularly in fields such as plastic and reconstructive surgery. Their compact and lightweight construction allows for precise manipulation in confined areas, making them ideal for handling fine sutures without causing tissue trauma. Surgeons appreciate the heightened control provided by Gillies needle drivers, facilitating secure needle grasping and accurate knot tying, which are essential for achieving optimal patient outcomes during intricate procedures.

Not all needle drivers serve the same purpose. Some are crafted for specific surgical tasks, each with its own importance in the operating room.

Specialty Needle Drivers for Specific Surgical Procedures

Specialty needle drivers serve distinct functions in various surgical fields, enhancing precision and effectiveness. Ryder needle drivers are instrumental in vascular surgery, allowing for delicate manipulation and suturing of blood vessels. Crile-Wood needle drivers excel in fine suturing applications, ensuring secure and effective closure. Halsey needle drivers find their niche in dental and plastic surgeries, delivering control during intricate procedures. Debakey needle drivers are tailored for cardiovascular techniques, facilitating precise handling in complex heart surgeries.

Using Ryder Needle Drivers in Vascular Surgery

Ryder needle drivers play a crucial role in vascular surgery by facilitating the delicate manipulation of blood vessels during procedures. Their design allows surgeons to achieve an optimal grip on sutures without risking damage to the fragile vascular tissues, which is essential for successful outcomes. For instance, when performing anastomosis, the precision and control provided by Ryder needle drivers help ensure secure knot tying, reducing the potential for complications such as bleeding or leakage in the postoperative phase.

Applications of Crile-Wood Needle Drivers in Fine Suturing

Crile-Wood needle drivers are highly regarded for their applications in fine suturing, particularly in delicate procedures such as vascular and plastic surgery. Their design features finely tapered jaws that provide surgeons with a precise grip on thin sutures, ensuring secure knot tying without damaging surrounding tissues. This is especially crucial in operations where minimizing trauma is essential for optimal healing, making Crile-Wood needle drivers a preferred choice among surgeons aiming for high-quality outcomes. Micro surgery needle holders

Halsey Needle Drivers in Dental and Plastic Surgeries

Halsey needle drivers are specifically designed for use in dental and plastic surgeries, where precision and control are paramount. Their unique characteristics, including fine jaws and a secure grip, allow surgeons to manipulate delicate sutures effectively without causing tissue trauma. This capability is particularly essential in procedures like skin grafting or facial reconstructive surgeries, where maintaining the integrity of surrounding tissues is critical for optimal healing and aesthetic results.

- Designed for precision in dental and plastic surgeries.

- Features fine jaws for secure gripping of delicate sutures.

- Minimizes tissue trauma during critical surgical procedures.

- Essential for skin grafting and facial reconstructive surgeries.

Debakey Needle Drivers for Cardiovascular Techniques

Debakey needle drivers are specifically designed for use in cardiovascular techniques, providing surgeons with the precision and control necessary for delicate procedures involving the heart and blood vessels. Their tapered jaws allow for a secure grip on fine sutures, which is critical during intricate surgeries such as coronary artery bypass grafting and valve repairs. The ergonomic design of Debakey needle drivers reduces hand fatigue, thus promoting efficiency and accuracy throughout lengthy surgical interventions.

Choosing the right needle driver can shape the success of a procedure. Next, the essential factors will guide this important decision.

Factors to Consider When Choosing a Needle Driver

Choosing the right needle driver is critical for successful surgical procedures. Key factors include matching the needle driver size to suture requirements, evaluating surgeon comfort through ergonomics, assessing material durability and longevity, and ensuring sterilization compatibility and maintenance needs. Understanding these considerations will help optimize the selection process, leading to better surgical outcomes and enhanced efficiency.

Matching Needle Driver Size to Suture Requirements

When selecting a needle driver, it is essential to match the instrument’s size with the specific suture requirements for the surgical procedure. For instance, larger needle drivers may be more suitable for robust sutures used in general surgery, while finer needle drivers are typically preferred for delicate tasks in areas such as microsurgery. The right size ensures better control and precision during suturing, ultimately leading to improved patient outcomes.

| Needle Driver Size | Suture Type | Recommended Surgical Procedures |

|---|---|---|

| Large | Robust sutures | General surgery, orthopedic surgery |

| Medium | Standard sutures | Plastic surgery, reconstructive surgery |

| Small | Fine sutures | Microsurgery, ophthalmic surgery |

Evaluating Surgeon Comfort and Ergonomics

Evaluating surgeon comfort and ergonomics is crucial when selecting a needle driver for surgical procedures. Ergonomically designed needle drivers feature comfortable grips and appropriate handle shapes that reduce hand fatigue during lengthy operations. Ensuring that the instrument fits well within the surgeon‘s hand can significantly enhance dexterity and control, ultimately leading to improved precision and outcomes in delicate suturing tasks.

Assessing Material Durability and Longevity

When assessing material durability and longevity in needle drivers, surgeons must consider factors such as corrosion resistance and the ability to withstand repeated sterilization. Instruments made from stainless steel are widely preferred due to their durability and sufficient resistance to wear, ensuring they remain effective over time. In contrast, tungsten carbide needle drivers offer superior hardness and sharp precision, making them particularly suitable for demanding surgical environments, where maintaining the integrity of the instrument is essential for optimal patient care.

| Material | Durability | Typical Uses |

|---|---|---|

| Stainless Steel | Corrosion-resistant and durable | General and orthopedic surgery |

| Tungsten Carbide | Superior hardness and precision | Microsurgery and intricate procedures |

Sterilization Compatibility and Maintenance Needs

When selecting a needle driver, surgeons must prioritize sterilization compatibility and maintenance needs to ensure the instrument’s longevity and effectiveness. Most needle drivers are designed for repeated sterilization, with stainless steel options being particularly favored for their corrosion resistance and ability to endure rigorous cleaning protocols. Understanding the specific maintenance requirements for different materials, such as ensuring proper drying and safe storage, minimizes the risk of contamination and prolongs the operational lifespan of these essential surgical tools.

A good needle driver is only as strong as its care. Proper maintenance can extend its life and effectiveness; knowing how to care for these tools is vital.

Maintenance and Care for Surgical Needle Drivers

Effective maintenance and care for surgical needle drivers are essential to ensure their longevity and performance. Proper post-surgical cleaning methods will be discussed first, followed by the importance of inspecting for wear and potential damage. The procedures for sharpening and re-tipping will be examined next, along with best practices for storage and preservation, all vital for maintaining the functionality of these critical surgical instruments.

Proper Post-Surgical Cleaning Methods

Proper post-surgical cleaning methods for needle drivers are essential for maintaining their performance and ensuring longevity. It is crucial to follow a thorough cleaning protocol immediately after use, which typically involves wiping the instruments with an appropriate disinfectant to remove biological material. After initial cleaning, needle drivers should be sterilized using an autoclave to eliminate any remaining pathogens, ensuring they are safe and ready for future procedures.

Inspecting for Wear and Potential Damage

Regular inspection for wear and potential damage of surgical needle drivers is crucial in maintaining their functionality and safety during procedures. Surgeons should closely examine the instrument’s jaws and locking mechanisms for signs of wear, such as nicks or irregularities that could compromise grip and accuracy. Identifying these issues early can prevent complications and ensure that needle drivers perform optimally, safeguarding patient safety and enhancing surgical outcomes:

- Examine instrument for visible wear, focusing on jaws and locks.

- Check for smooth operation of ratchet mechanisms.

- Consider periodic professional servicing to maintain quality.

- Replace any damaged needle drivers promptly to avoid risks.

Procedures for Sharpening and Re-Tipping

The procedures for sharpening and re-tipping needle drivers are vital for maintaining their efficiency and integrity. Surgeons should utilize specialized sharpening tools designed for surgical instruments to ensure precision during the process, as improper techniques can compromise performance. Regular re-tipping, particularly for those with tungsten carbide jaws, helps retain a reliable grip on sutures, thus minimizing risks of slippage and enhancing overall surgical outcomes.

Best Practices for Storage and Preservation

Best practices for storing and preserving surgical needle drivers play a crucial role in maintaining their functionality and longevity. After each use, needle drivers should be cleaned and dried thoroughly before being stored in a designated, organized space that prevents clashing with other instruments, reducing the risk of damage. Utilizing protective cases or trays specifically designed for surgical instruments can help maintain their integrity and ensure they are readily accessible when needed: protective cases or trays

| Storage Method | Benefits |

|---|---|

| Storage Trays | Prevent clashing and maintain organization. |

| Protective Cases | Safeguard against physical damage and contamination. |

| Regular Inspections | Ensure functionality and identify wear or damage. |

| Labeling | Facilitates easy identification and access during surgeries. |

Conclusion

Understanding the various types of needle drivers used in surgical procedures is crucial for enhancing surgical precision and outcomes. Each design—whether straight, curved, locking, or non-locking—serves specific functions tailored to the requirements of different surgical specialties. By selecting the appropriate needle driver based on size, material, and ergonomics, surgeons can optimize their suturing techniques, leading to better patient care. This comprehensive knowledge not only improves efficiency during operations but also minimizes the risks associated with surgical interventions.